CAPABILITIES

Redundancy is built in throughout our facility to meet your needs without interruption. With that in mind, Excal Inc. offers the following capabilities...

-A robust pattern shop for building new tools and servicing existing tooling. Most tools can be utilized with small adaptations. We are known for taking good care of your tooling.

-Three options for core materials utilizing several machines, including our custom Palmer Coremaker. We can produce high volumes of complex cores daily.

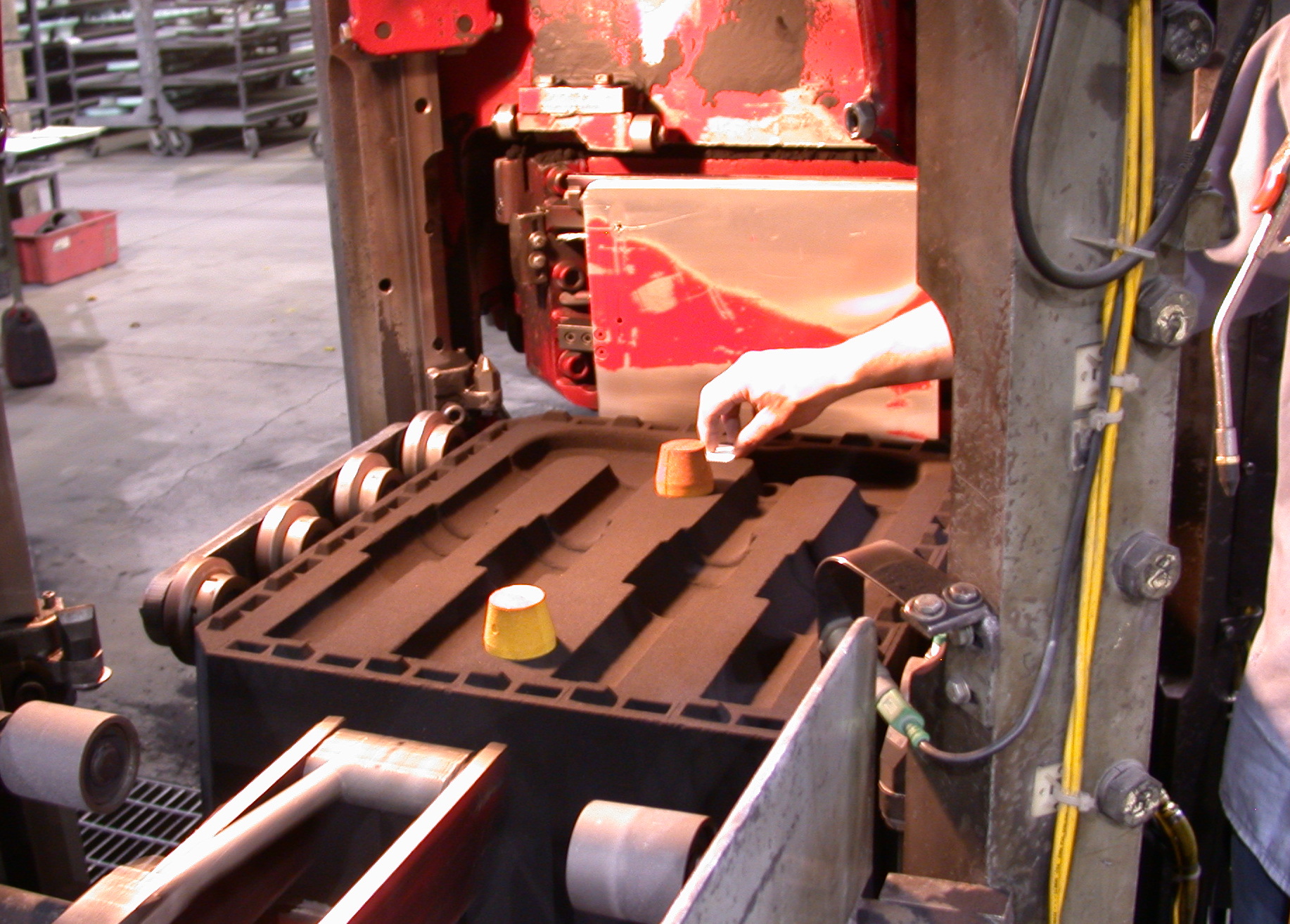

-Two high production green sand molding and pouring lines capable of producing castings of multiple alloys in a single shift. Each line is independent for redundancy and versatility.

-Two air set/no-bake molding lines with one for high volume production and one for low volume specialty builds and prototyping. Both are capable of castings from one pound to thousands of pounds.

-Four independent melting furnaces with a combined capacity of 80,000 lbs of metal daily and up to 5,000 lbs in a single pour.

-An expansive cleaning room with multiple cutting and grinding options for all types and sizes of castings.

-One in-house heat treat furnace for brasses, bronzes and stainless alloys.

-Five CNC turning centers, two CNC mills and support equipment for your machining needs.

- An in-house spectrometer for brass, bronze, aluminum and stainless steel.

-A huge building with room for future expansion and enough unused acreage to double in size.

-A robust ERP system for order management, quality control, purchasing and servicing capabilities.